During Production Inspections (DUPRO)

What Is During Production Inspection?

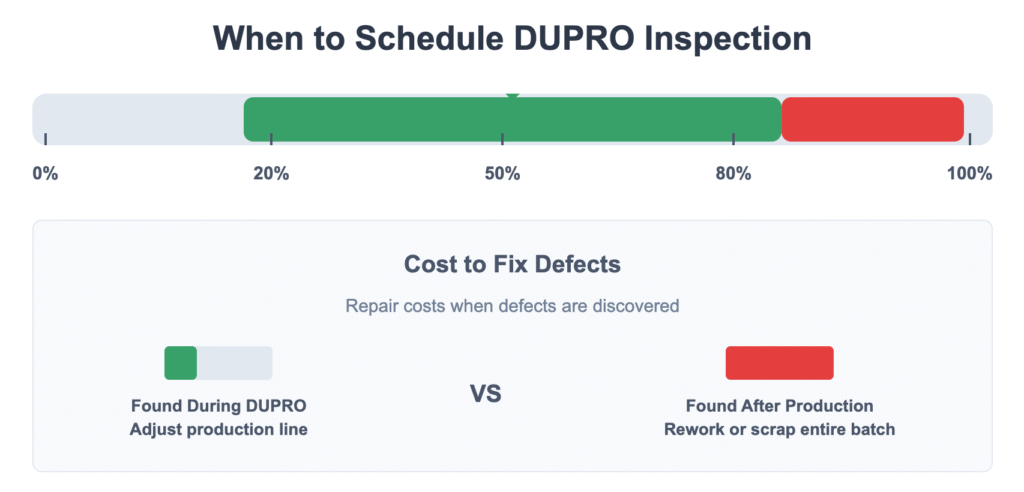

A During Production Inspection (DUPRO) also called In-Process Inspection, IPQC, or Inline Quality Inspection is performed when 20–80% of an order is complete. Instead of waiting until production finishes, we inspect while goods are still being made, catching problems when they’re fast and affordable to fix.

QCI.Asia provides DUPRO inspection services across Vietnam, China, Thailand, and the Philippines, following AQL (Acceptable Quality Limit) standards with structured defect classification.

💡 Planning your next shipment?

Use our free AQL Calculator to find the right sample size and acceptance criteria for your inspection.

When You Need DUPRO Inspection

Key scenarios for mid-production inspection:

- Timeline pressure – Tight deadlines where you can’t afford to find problems at final inspection

- Production issues emerging – Factory reports quality problems and you need to assess the scope

- Complex assembly processes – Multi-step products where early defects compound through the entire process

During Production Inspection Vietnam

Our DUPRO inspection services in Vietnam provide same-day scheduling across Ho Chi Minh City, Hanoi, and all major industrial zones.

Coverage: Binh Duong, Dong Nai, Long An, Bac Ninh, Hung Yen, Da Nang

Scheduling: Same-day or next-day inspection available

Report Delivery: Within 24 hours

During Production Inspection China

We provide DUPRO inspection services across major Chinese manufacturing hubs through our vetted inspector network.

Coverage: Shenzhen, Guangzhou, Dongguan, Shanghai, Ningbo, Yiwu

Scheduling: 48-72 hours from confirmation

Report Delivery: Within 24 hours

Reliable Third-Party In-Process Inspection: Our experienced inspectors with over 15 years' factory experience provide factory in-process inspection Asia expertise.

Advanced Technology: Our proprietary inspection app ensures consistent procedures and structured defect data, giving you accuracy traditional quality inspection during manufacture misses.

Smart Defect Tracking: Each defect is classified and logged into our standardized defect database, allowing you to track trends and compare supplier performance across factories.

Video Evidence: HD video and photo documentation with QR-coded evidence links for full traceability and easier supplier communication.

Our Professional IPQC Inspection Service covers: Production line quality control assessment, material verification, workmanship sampling, packaging review, and timeline evaluation. We recommend scheduling when your factory reaches 30–50% production completion.

Coverage: Vietnam (same-day), China (48-72 hours), Thailand & Philippines (24-48 hours). Reports delivered within 24 hours.